Plastic injection molding is at the heart of modern manufacturing. It’s the process behind many of the products we use every day — from automotive components and medical devices to packaging and electronics. With its ability to produce complex shapes quickly and with consistent quality, injection molding has become the go-to method for large-scale plastic part production.

In this guide, we’ll walk through what plastic injection molding is, how it works, the materials involved, design tips, and the latest trends shaping the industry.

Modern manufacturers, like LZ tooling, turn to plastic injection molding for durable, precise, and visually refined components and deliver custom injection molding solutions using advanced machines, high-performance polymers, and precision tooling. Through controlled processing and strict quality inspection, they ensure consistent strength, accuracy, and efficiency—showing how engineering expertise and tooling excellence drive superior product performance and design.

- What Is Plastic Injection Molding?

- The Injection Molding Process Explained

- 1. Clamping

- 2. Injection

- 3. Cooling

- 4. Ejection

- Common Materials for Injection Molding

- Different Types of Injection Molding Processes

- Standard Injection Molding

- Overmolding

- Insert Molding

- Gas-Assisted Injection Molding

- Two-Shot (Multi-Material) Molding

- Micro Injection Molding

- Advantages of Plastic Injection Molding

- Design Tips for Injection Molded Parts

- Applications of Injection Molding

- Challenges in Injection Molding

- Choosing the Right Injection Molding Partner

- Future Trends in Injection Molding

- Conclusion

What Is Plastic Injection Molding?

Plastic injection molding is a production process used to create parts by injecting molten plastic into a precisely designed mold cavity. Once cooled and solidified, the plastic forms a permanent shape that can be removed, finished, and used immediately or as part of a larger assembly.

It’s one of the most efficient and repeatable manufacturing techniques available — capable of producing everything from small, intricate components to large structural pieces with exceptional precision.

The Injection Molding Process Explained

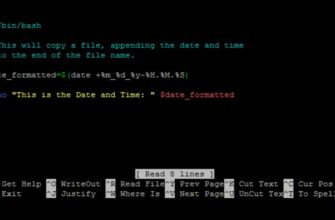

Although it operates in just seconds, the injection molding process involves several carefully timed steps. Understanding each stage helps explain why the method is so reliable and scalable.

1. Clamping

The mold consists of two halves: the core and the cavity. The clamping unit closes and secures these halves tightly to prepare for injection.

2. Injection

Plastic pellets are fed into a heated barrel, melted, and then injected into the mold cavity under high pressure. This ensures the material fills every corner of the design.

3. Cooling

Once filled, the molten plastic begins to cool and solidify. Cooling time depends on part thickness and the material used.

4. Ejection

After cooling, the mold opens, and ejector pins push the finished part out. The mold then closes again to start the next cycle.

A complete cycle can take just a few seconds for small parts or up to a minute for larger components, making the process extremely efficient for mass production.

Common Materials for Injection Molding

Material selection is a critical step in achieving the desired performance and appearance of a molded part. The right resin impacts strength, flexibility, durability, and cost. Below are some commonly used thermoplastics in injection molding:

- ABS (Acrylonitrile Butadiene Styrene) – Strong, tough, and impact-resistant. Often used in electronics, tools, and automotive components.

- Polypropylene (PP) – Lightweight, flexible, and chemically resistant. Ideal for packaging, medical devices, and household products.

- Polycarbonate (PC) – Transparent and impact-resistant, used for lenses, lighting covers, and safety equipment.

- Nylon (PA) – Durable, wear-resistant, and strong, perfect for gears, mechanical parts, and connectors.

- Polyethylene (PE) – Flexible and moisture-resistant; commonly used in bottles, film, and containers.

- POM (Acetal) – Low friction and high stiffness; often used for precision components and moving parts.

Modifiers and fillers such as glass fibers, colorants, flame retardants, and UV stabilizers can be added to customize material performance.

Different Types of Injection Molding Processes

Injection molding is not a one-size-fits-all process. Several variations exist to meet different technical and aesthetic requirements.

Standard Injection Molding

The most common form — molten plastic is injected into a mold to create solid parts with consistent quality and high repeatability.

Overmolding

Combines two or more materials in one product. A soft elastomer is molded over a rigid base to improve grip, comfort, or appearance.

Insert Molding

Metal or preformed inserts are placed in the mold before injection, allowing the plastic to bond around them — great for threaded or electrical components.

Gas-Assisted Injection Molding

Pressurized gas is injected alongside the molten plastic to create hollow sections, reducing weight and improving surface finish.

Two-Shot (Multi-Material) Molding

Enables the production of parts with multiple colors or materials in one cycle — popular in consumer electronics and automotive interiors.

Micro Injection Molding

Used for producing ultra-small, precise parts found in medical and electronic devices.

Each technique offers unique advantages depending on the design complexity and performance requirements.

Advantages of Plastic Injection Molding

The widespread use of injection molding is no coincidence — it offers several clear benefits over alternative manufacturing processes:

- High Production Efficiency – Once the mold is made, parts can be produced rapidly in large quantities.

- Exceptional Repeatability – Each cycle produces identical parts, ensuring consistency and quality.

- Complex Geometries Possible – Intricate shapes, fine details, and textured surfaces are easily achieved.

- Material Versatility – Thousands of plastic resins and blends are available for specific needs.

- Minimal Waste – Excess material can be reground and reused, reducing waste.

- Low Per-Unit Cost – Although molds can be costly, the price per part becomes very low at scale.

For manufacturers seeking precision, durability, and cost-effectiveness, injection molding remains unmatched.

Design Tips for Injection Molded Parts

Designing for injection molding requires a balance between functionality, manufacturability, and cost efficiency. Below are key principles to consider during part design:

- Maintain Uniform Wall Thickness – Prevents warping and ensures consistent cooling.

- Add Draft Angles – A slight taper (1–2°) helps parts eject smoothly from the mold.

- Use Ribs and Bosses for Strength – Reinforce parts without adding unnecessary thickness.

- Plan Gate Locations Carefully – Strategic placement ensures even flow and reduces visible marks.

- Avoid Sharp Corners and Undercuts – Simplifies tooling and improves part longevity.

- Account for Shrinkage – Plastics shrink as they cool; accurate prediction prevents dimensional issues.

Designing with these principles in mind leads to more reliable molds and higher-quality finished parts.

Applications of Injection Molding

Plastic injection molding is incredibly versatile. It supports industries ranging from healthcare to construction, providing durable and aesthetic components at scale.

- Automotive. Bumpers, dashboards, clips, and interior panels.

- Medical. Syringes, housings, and diagnostic components.

- Consumer Goods.. Toys, appliance casings, and personal care products.

- Electronics. Connectors, enclosures, and precision micro parts.

- Packaging. Bottle caps, closures, and food containers.

- Industrial and Construction. Fittings, handles, and protective covers.

The ability to combine performance, design flexibility, and cost control makes injection molding indispensable across global manufacturing sectors.

Challenges in Injection Molding

Despite its strengths, injection molding does come with challenges that engineers and manufacturers must address:

- High Tooling Costs. Molds are expensive to design and fabricate, especially for complex parts.

- Material Shrinkage. All plastics contract during cooling, requiring precise compensation in mold design.

- Process Optimization. Temperature, pressure, and cooling must be carefully balanced for best results.

- Surface Defects. Flow lines, weld marks, or sink marks can occur if conditions aren’t optimal.

Careful design validation and advanced simulation tools can help identify and fix these issues before production begins.

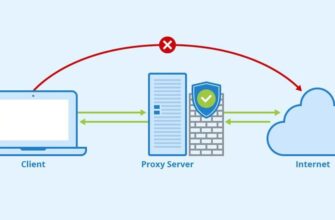

Choosing the Right Injection Molding Partner

Finding a capable manufacturing partner is essential for achieving quality and cost goals. When evaluating suppliers, consider:

- Engineering Expertise – Experience in mold design, simulation, and process optimization.

- In-House Tooling Capabilities – Integrated design and machining improve precision and turnaround time.

- Quality Systems – ISO-certified processes and rigorous inspections ensure consistency.

- Material Knowledge – Understanding the best resins and additives for your application.

- Scalability – Ability to handle both prototyping and mass production efficiently.

- Technical Support – Reliable communication and troubleshooting throughout the project lifecycle.

A well-rounded partner helps you minimize costs, avoid design pitfalls, and deliver parts that perform as intended.

Future Trends in Injection Molding

The injection molding industry is embracing advanced technologies that enhance speed, precision, and sustainability.

Key trends include:

- Industry 4.0 Integration: Smart sensors and real-time data monitoring for predictive maintenance.

- 3D Printed Molds: Additive manufacturing shortens tooling lead times and enables rapid prototyping.

- Lightweight Composites: Increased use of carbon fiber and glass-filled polymers for strength without added weight.

- Micro and Nano Molding. Growth in demand for ultra-precise components in medical and electronic fields.

- Circular Manufacturing. Emphasis on recycling and material recovery to achieve closed-loop production.

These advancements are reshaping injection molding into a faster, smarter, and more sustainable process.

Conclusion

Plastic injection molding continues to define modern manufacturing — offering a perfect balance of efficiency, accuracy, and versatility. From small precision components to large structural parts, it remains the preferred method for producing durable plastic products at scale.

By understanding the process, materials, and design considerations, engineers and manufacturers can unlock new levels of performance and innovation. And as technology continues to evolve, injection molding will remain at the forefront of global production — driving smarter, more sustainable solutions across industries.